gcode Files: A Comprehensive Guide for Enthusiasts and Professionals

Have you ever wondered what gcode files are and how they play a crucial role in the world of CNC machining? If you’re new to this field or looking to expand your knowledge, you’ve come to the right place. In this detailed guide, we’ll delve into the intricacies of gcode files, their significance, and how they can enhance your CNC machining experience.

What is a gcode File?

A gcode file, also known as a G-code file, is a text file that contains instructions for a computer numerical control (CNC) machine. These instructions are used to control the movement of the machine’s tool, such as a milling cutter or a lathe, to produce a desired shape or feature on a workpiece.

At its core, gcode is a language that consists of a series of alphanumeric characters and symbols. Each line in a gcode file represents a specific command or instruction for the CNC machine. These commands can range from simple movements, such as moving the tool to a specific position, to more complex operations, such as cutting or drilling.

Understanding the Structure of a gcode File

Let’s take a closer look at the structure of a typical gcode file. A gcode file is composed of several components, including:

| Component | Description |

|---|---|

| Header | Contains information about the file, such as the machine model, tooling, and version of the gcode. |

| Initialization Commands | Set up the machine for operation, such as setting the tool offset, machine coordinates, and speed. |

| Movement Commands | Control the movement of the tool, such as linear, circular, or helical movements. |

| Tool Commands | Manage the tool, such as changing the tool, setting the tool offset, and controlling the tool’s speed and feed rate. |

| End Commands | Indicate the end of the program, such as resetting the machine to its initial state or performing a tool change. |

Understanding the structure of a gcode file is essential for creating and editing these files effectively. By familiarizing yourself with the various components, you’ll be better equipped to control your CNC machine and achieve the desired results.

Creating and Editing gcode Files

Creating and editing gcode files can be done using various software tools, such as CAM (Computer-Aided Manufacturing) software, text editors, or specialized gcode editors. Here’s a brief overview of the process:

-

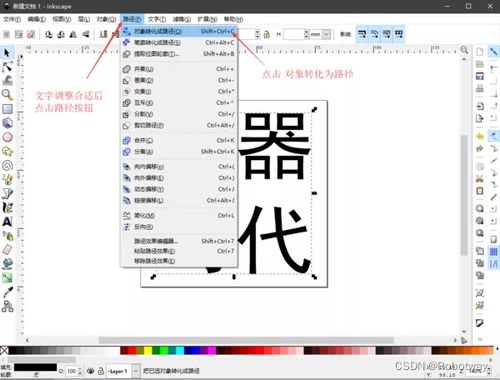

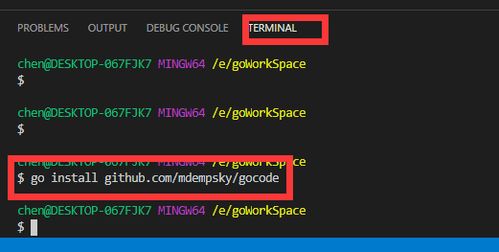

Choose a suitable CAM software or text editor to create your gcode file.

-

Design your part or feature using the software’s design tools.

-

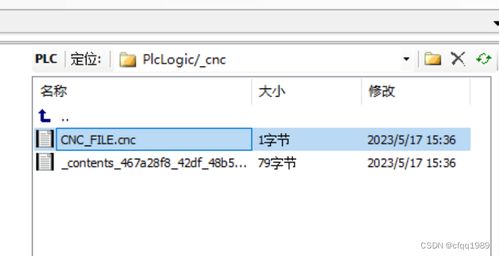

Generate the gcode file by exporting the design as a gcode file.

-

Review and edit the gcode file as needed, using the software’s editing features or a text editor.

-

Upload the gcode file to your CNC machine and start the machining process.

When editing a gcode file, it’s important to pay attention to the syntax and ensure that the commands are correctly formatted. Even a small typo or missing character can cause the machine to behave unexpectedly or produce inaccurate results.

The Benefits of Using gcode Files

Using gcode files offers several benefits for CNC machining enthusiasts and professionals alike:

-

Increased Precision: Gcode files allow for precise control over the machine’s movements, resulting in highly accurate parts.

-

Flexibility: Gcode files can be easily modified and adapted to suit different machining requirements.

-

Cost-Effective: Gcode files can be used to optimize the machining process, reducing material waste and labor costs.

-

Customization: Gcode files enable the creation of unique and complex parts that may not be achievable using traditional manufacturing methods.