Pcb Stator Design Files: A Comprehensive Guide

Designing a PCB stator requires a meticulous approach, combining electrical engineering principles with practical manufacturing considerations. As you delve into the world of PCB stator design files, it’s crucial to understand the various aspects that contribute to a successful design. This article will walk you through the process, providing you with a detailed overview of PCB stator design files, their importance, and how to create them effectively.

Understanding PCB Stator Design Files

PCB stator design files are essential for the manufacturing of stators used in various applications, such as electric motors, generators, and transformers. These files contain all the necessary information for producing a stator with the required specifications. Typically, these files are in the form of Gerber files, which are industry-standard files used for PCB manufacturing.

Gerber files consist of multiple layers, each representing a different aspect of the PCB design. These layers include the copper layers, soldermask, silk screen, and drill files. By understanding these layers, you can ensure that your PCB stator design files are complete and accurate.

Creating PCB Stator Design Files

Creating PCB stator design files involves several steps, from initial design to finalizing the Gerber files. Here’s a detailed guide to help you through the process:

-

Design the Stator

-

Choose the Right Software

-

Set Up the Design Rules

-

Draw the Stator Layers

-

Generate Gerber Files

-

Review and Verify the Files

Designing the Stator

The first step in creating PCB stator design files is to design the stator itself. This involves determining the required specifications, such as the number of poles, the winding configuration, and the material properties. You’ll also need to consider the overall size and shape of the stator, as well as any additional features, such as cooling channels or mounting holes.

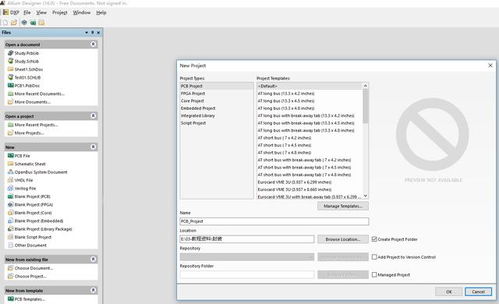

Once you have a clear understanding of the stator’s requirements, you can begin the design process. This can be done using various CAD software packages, such as Altium Designer, EAGLE, or KiCad. These tools provide the necessary features to create detailed stator designs, including 2D and 3D modeling capabilities.

Choosing the Right Software

Selecting the appropriate software for your PCB stator design is crucial for ensuring a smooth and efficient design process. Here are some popular options to consider:

| Software | Description |

|---|---|

| Altium Designer | Industry-standard PCB design software with advanced features for complex stator designs. |

| EAGLE | Popular among hobbyists and small businesses, offering a user-friendly interface and a wide range of design tools. |

| KiCad | Open-source PCB design software that provides a comprehensive set of tools for creating professional-grade designs. |

Setting Up the Design Rules

Before you start drawing the stator layers, it’s essential to set up the design rules. These rules define the constraints and requirements for your PCB design, such as the minimum trace width, spacing, and clearance. By adhering to these rules, you can ensure that your PCB stator design files are manufacturable and meet the required specifications.

Most PCB design software allows you to define design rules within the project settings. You can specify the rules for each layer, such as copper, soldermask, and silk screen, ensuring that all aspects of your design are accounted for.

Draw the Stator Layers

With the design rules in place, you can now start drawing the stator layers. This involves creating the copper layers, which define the winding paths, as well as the soldermask and silk screen layers, which provide visual guidance and protect the copper layers during manufacturing.

When drawing the stator layers, pay close attention to the following aspects:

-

Trace Width and Spacing

-

Layer Stackup