3D Printing File After Slicing: A Comprehensive Guide

Embarking on a 3D printing journey can be both exciting and challenging. One of the most crucial steps in this process is slicing, which involves converting your 3D model into a format that the printer can understand. Once slicing is complete, you’re left with a 3D printing file, which is the blueprint for your creation. In this article, we’ll delve into the intricacies of a 3D printing file after slicing, exploring its various aspects to help you better understand and utilize it.

Understanding the Sliced File

A sliced file is essentially a set of instructions that tells your 3D printer how to build your model layer by layer. These instructions include information about the printer’s movement, extruder settings, and other parameters. Let’s take a closer look at the key components of a sliced file:

| Component | Description |

|---|---|

| Layer Height | The thickness of each layer of the printed object. A smaller layer height results in a smoother finish but requires more time and material. |

| Print Speed | The speed at which the printer moves the extruder. A slower speed can improve print quality but may increase the print time. |

| Temperature Settings | The temperature at which the printer’s extruder and bed should be set. These settings depend on the type of filament being used. |

| Support Structures | Small structures that the printer creates to support overhanging parts of the model. These structures are removed after printing. |

These are just a few examples of the many parameters that can be adjusted in a sliced file. The right combination of settings will depend on your specific printer, filament, and design requirements.

Opening and Editing a Sliced File

Once you have a sliced file, you may need to open and edit it to fine-tune your print settings. Here’s how you can do it:

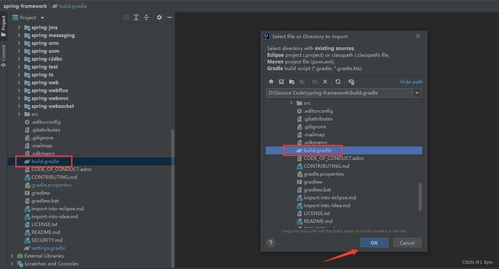

- Choose a slicing software that is compatible with your printer and model. Some popular options include Cura, PrusaSlicer, and Simplify3D.

- Open the slicing software and import your sliced file.

- Review the print settings and make any necessary adjustments. You can change the layer height, print speed, temperature, and other parameters.

- Save your modified sliced file.

It’s important to note that editing a sliced file can be a complex process, especially if you’re new to 3D printing. However, with practice, you’ll become more comfortable with the software and its features.

Printing Your Sliced File

After you’ve finalized your sliced file, it’s time to print your model. Here’s a step-by-step guide to help you through the process:

- Load your filament into the printer and set the appropriate temperature.

- Position your model on the printer’s bed and secure it in place.

- Start the print job. The printer will begin to extrude the filament and build your model layer by layer.

- Monitor the print process and make any necessary adjustments, such as repositioning the model or adjusting the extruder temperature.

- Once the print is complete, remove the model from the printer and clean it if necessary.

Printing a 3D model can be a time-consuming process, but it’s worth the effort to see your creation come to life.

Common Challenges and Solutions

While 3D printing is a fascinating technology, it’s not without its challenges. Here are some common issues you may encounter and their potential solutions:

- Under extrusion: This occurs when the printer is not extruding enough filament. To fix this, check the extruder temperature and ensure that the filament is properly loaded.

- Over extrusion: This happens when the printer is extruding too much filament. Adjust the extruder temperature and re-slice your model with a lower extrusion multiplier.

- Bed adhesion issues: