How to Edit a DCTL File: A Comprehensive Guide

Editing a DCTL file can be a daunting task, especially if you’re not familiar with the file format or the software used to create it. DCTL files are commonly used in CNC (Computer Numerical Control) programming, where they define tool paths for cutting machines. Whether you’re a beginner or an experienced user, this guide will walk you through the process of editing a DCTL file step by step.

Understanding DCTL Files

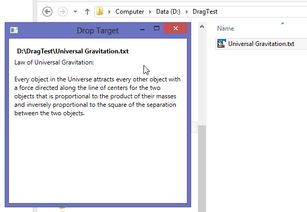

DCTL files are text-based files that contain instructions for CNC machines. They are typically used in conjunction with CAM (Computer-Aided Manufacturing) software to generate tool paths. The file format is based on G-code, which is a standard language used in CNC programming.

Here’s a basic structure of a DCTL file:

| Line Number | Command | Description |

|---|---|---|

| 1 | M3 | Spindle on, clockwise rotation |

| 2 | G0 X0 Y0 Z0 | Move to home position |

| 3 | G1 X10 Y10 F100 | Move to point (10, 10) at a feed rate of 100 |

Now that you have a basic understanding of the file format, let’s dive into the editing process.

Editing a DCTL File

1. Open the DCTL File

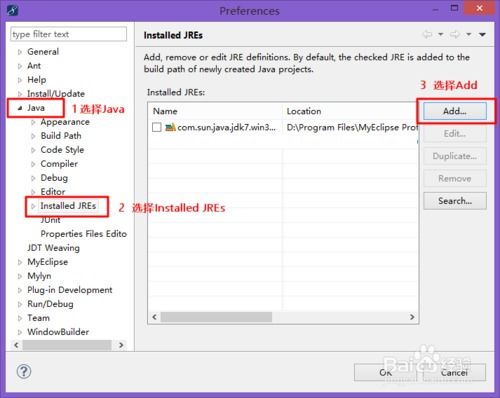

First, you need to open the DCTL file using a text editor or a specialized CNC software. Some popular text editors include Notepad++, Sublime Text, and Atom. If you’re using a specialized CNC software, it may have a built-in editor that allows you to view and modify the DCTL file directly.

2. Review the File

Before making any changes, it’s essential to review the file to understand its structure and the tool paths it defines. Look for commands like G0 (rapid positioning), G1 (linear interpolation), and G2/G3 (circular interpolation). Pay attention to the coordinates, feed rates, and spindle speeds.

3. Make Changes

Now that you have a good understanding of the file, you can start making changes. Here are some common modifications you might need to make:

-

Change the coordinates: If you need to move the tool to a different position, simply modify the X, Y, and Z coordinates in the G1 commands.

-

Adjust the feed rate: The feed rate determines how fast the tool moves along the tool path. You can increase or decrease the feed rate by modifying the F value in the G1 commands.

-

Change the spindle speed: The spindle speed controls the rotation of the cutting tool. You can adjust the spindle speed by modifying the S value in the M3 command.

-

Modify the tool path: If you need to change the shape or size of the part being machined, you’ll need to modify the G1, G2, and G3 commands accordingly.

4. Save the File

After making the necessary changes, save the file. It’s crucial to ensure that the file is saved in the correct format (e.g., .dctl) to avoid any compatibility issues with your CNC machine.

Testing the DCTL File

Before running the program on your CNC machine, it’s essential to test the DCTL file to ensure that it works as expected. You can do this by simulating the tool path using your CAM software or by running a dry run on the machine. This will help you identify any potential issues, such as collisions or incorrect tool paths, before they cause damage to your machine or workpiece.

Additional Tips

-

Use a consistent coordinate system: Ensure that all your coordinates are in the same system (e.g., metric or imperial) to avoid errors.

-

Keep your file organized: Use comments and consistent formatting to make your DCTL file easy to read and understand.