Understanding CNC Files: A Comprehensive Guide

CNC files are the backbone of modern manufacturing processes. They are digital blueprints that guide CNC machines in producing intricate parts and products with high precision. Whether you are a hobbyist, engineer, or manufacturer, understanding CNC files is crucial for successful CNC operations. In this article, we will delve into the intricacies of CNC files, their formats, and how they are used in the manufacturing process.

What is a CNC File?

A CNC file, also known as a Computer Numerical Control file, is a digital representation of a physical object or part. It contains instructions that tell a CNC machine how to move its cutting tools to shape the material into the desired form. These files are typically created using Computer-Aided Design (CAD) software and can be in various formats, such as G-code, STL, or DXF.

Types of CNC Files

There are several types of CNC files, each with its unique characteristics and applications:

| File Type | Description | Common Uses |

|---|---|---|

| G-code | Text-based instructions for CNC machines | Machine control, tool movement, and material removal |

| STL | Surface description file format | 3D printing, rapid prototyping, and CAD modeling |

| DXF | Binary file format for CAD data exchange | CAD modeling, CAM software input, and CNC machine control |

Creating CNC Files

CNC files are created using CAD software, which allows designers to create detailed 2D or 3D models of their products. Once the design is complete, the software can generate the necessary CNC files. Here’s a brief overview of the process:

- Design the part or product using CAD software.

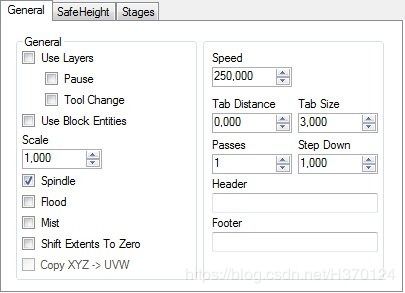

- Set up the design for CNC machining, including tool paths, material properties, and machine settings.

- Export the design as a CNC file in the desired format.

- Review and modify the CNC file as needed.

Using CNC Files

Once you have a CNC file, you can use it to control a CNC machine and produce the desired part or product. Here’s a step-by-step guide on how to use a CNC file:

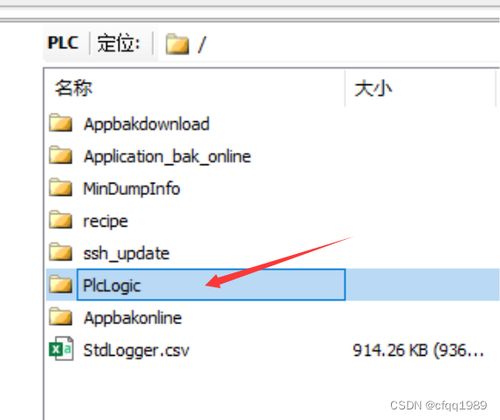

- Load the CNC file into the CNC machine’s control software.

- Set up the machine for the job, including tool selection, material setup, and machine zeroing.

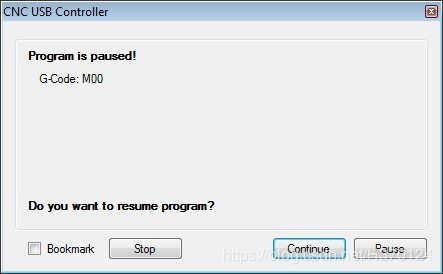

- Start the CNC machine and monitor the process.

- Inspect the finished part for quality and accuracy.

Common CNC File Formats and Software

Several CNC file formats and software options are available for creating and using CNC files:

- File Formats:

- G-code

- STL

- DXF

- IGES

- STEP

- Software:

- AutoCAD

- SolidWorks

- CATIA

- Creo

- Siemens NX

Conclusion

Understanding CNC files is essential for anyone involved in the manufacturing process. By familiarizing yourself with the different file formats, creation process, and usage, you can ensure successful CNC operations and produce high-quality parts and products. Whether you are a hobbyist or a professional, investing time in learning about CNC files will pay off in the long run.